In the world of electrical DIY, selecting the right tools and components can mean the difference between a successful project and a potential mishap. Among these essential components, Connectors and Interfaces—especially wire connectors—play a crucial role in ensuring that connections are both safe and efficient. With various types of wire connectors available on the market, how can you make an informed choice? This article provides valuable insights into different types of wire connectors, helping you understand their unique features, applications, and advantages. Whether you’re a seasoned electrician or embarking on your first DIY project, a solid understanding of these connectors will be an invaluable guide in your electrical work.

Unlock a new level of efficiency with LinkSemi’s Excess Electronic Components Module, designed to streamline your inventory sales and minimize excess costs. We provide exceptional Cost Saving Opportunities in Electronic Components procurement through AI-driven insights and automated workflows. Additionally, our advanced Electronic Component Shortage Tool helps mitigate supply chain disruptions, ensuring smooth production and uninterrupted operational efficiency.

What Are Wire Connectors and When Do You Need to Use Them?

Wire connectors are specialized devices designed to link or terminate wire ends, ensuring a secure and effective electrical connection. At their core, these connectors serve as the bridge between separate wire segments, allowing for the smooth transmission of electrical currents. Like all types of wire connectors, their fundamental purpose is to maintain the integrity of the circuit, prevent short-circuits, and offer a safe method for modifications or extensions.

Wire connectors can come in handy in a number of scenarios:

- Installation and Repairs: Whether you’re setting up a new electrical system or making modifications to an existing one, connectors provide a dependable way to join wires, ensuring longevity and reliability.

- Safety Considerations: Loose or improperly joined wires can lead to electrical malfunctions, sparks, or even fires. Wire connectors help mitigate these risks by offering a stable connection point.

- Modularity: In complex electrical setups, there might be a need for regular modifications, expansions, or adjustments. Wire connectors enable such flexibility, allowing changes without the need for complete overhauls.

- Specialized Applications: Certain electrical scenarios may demand specific types of wire connectors. For instance, high-voltage environments might require specialized connectors to handle the increased load without faltering.

In essence, wire connectors are indispensable tools in the realm of electrical work. They not only ensure the proper functioning of electrical systems but also significantly enhance safety standards, making them an absolute necessity in both professional and personal electrical projects.

Types of Wire Connectors: 1. Twist-On Wire Connectors (Wire Nuts)

Working Principle of Twist-On Wire Connectors

Twist-on wire connectors, commonly referred to as wire nuts, are among the most ubiquitous types of wire connectors in the electrical business. Their primary function is to join two or more wire ends together. The working principle is straightforward: stripped ends of wires are aligned parallel to each other and then inserted into the wire nut. As the nut is twisted onto them, its threaded inner surface binds the wires together, ensuring a tight and secure connection.

Advantages and Disadvantages of Twist-On Wire Connectors

Advantages:

- Simplicity: Wire nuts are easy to use, requiring no specialized tools or extensive training.

- Reliability: When correctly applied, they offer a secure connection that’s resistant to accidental dislodgment.

- Versatility: They’re suitable for a wide range of wire gauges and combinations.

Disadvantages:

- Size Limitation: There’s a maximum number of wires or specific wire gauge that a single wire nut can accommodate.

- Not Waterproof: Traditional wire nuts aren’t suited for moist or wet environments unless specifically designed for such conditions.

- Potential for Incorrect Use: If not twisted securely, or if used with incompatible wire sizes, they can become a safety hazard.

Use Cases of Twist-On Wire Connectors

- Home Wiring Projects: Twist-on wire connectors are standard for household electrical tasks, including setting up light fixtures, ceiling fans, or other appliances.

- Extension of Wires: If a wire segment is short and needs extension, wire nuts come in handy to join the additional length securely.

- Temporary Connections: In scenarios where a connection might need frequent adjustments or is not meant to be permanent, wire nuts provide a quick and reversible solution.

- Repair Work: When repairing or replacing damaged sections of wiring, these connectors are used to re-establish the circuit’s continuity.

By understanding the nature and capabilities of twist-on wire connectors, users can harness their benefits while being aware of their limitations, ensuring safer and more efficient electrical work.

Types of Wire Connectors: 2. Push-In Wire Connectors

Working Principle of Push-In Wire Connectors

Push-in wire connectors, also known as push-fit or simply push connectors, are designed to offer a secure connection by merely pushing stripped wire ends into the connector’s ports. Inside each port, a spring-loaded clamp provides continuous pressure, ensuring that the wire is held firmly in place. As the wire is inserted, the clamp adjusts to the wire’s size, offering a tight grip that maintains electrical continuity.

Advantages and Disadvantages of Push-In Wire Connectors

Advantages:

- Efficiency: These types of wire connectors drastically reduce the time needed for wire installations compared to other methods, making them a favorite for large projects.

- Consistency: With a straightforward push-to-connect mechanism, these connectors offer a uniform connection quality, minimizing the chances of human error.

- Compact Design: Their sleek design allows for multiple connections in tight spaces, making them suitable for junction boxes or wall outlets.

Disadvantages:

- Removal Challenges: While they are designed for secure connections, this can also mean that removing wires, especially from older connectors, can be a bit tricky.

- Compatibility: Not all push-in connectors are compatible with every wire type or gauge. It’s essential to ensure compatibility before installation.

- Dependence on Wire Quality: Push-in connectors rely on the integrity of the wire’s solid core. Frayed or damaged wires might not secure properly.

Use Cases of Push-In Wire Connectors

- Modern Electrical Installations: Their efficiency and consistency make push-in connectors a preferred choice for many contemporary electrical setups, such as in smart homes.

- Circuit Board Connections: Due to their compact nature, they are often used in circuit boards where space is a premium.

- Lighting Installations: Ideal for connecting wires in lighting fixtures, especially when multiple connections are required within a confined area.

- Prefabricated Wiring Systems: Push-in connectors are increasingly found in prefabricated wiring systems or modular electrical components due to their ease of use and reliable connection quality.

With their straightforward application and reliable performance, push-in wire connectors have carved a niche in modern electrical installations, bridging the gap between efficiency and consistency.

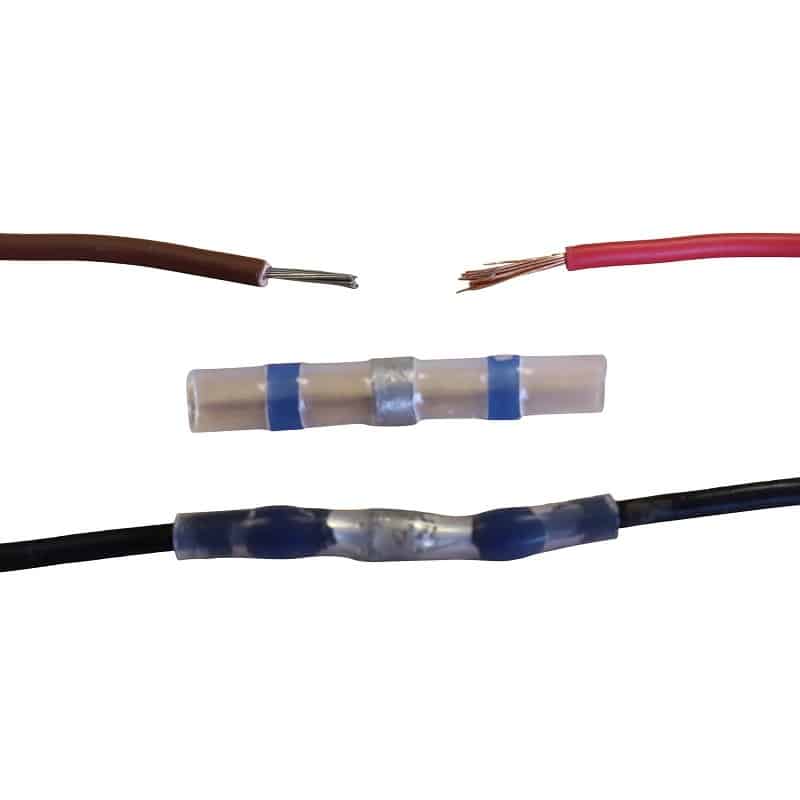

Types of Wire Connectors: 3. Crimp Wire Connectors

Working Principle of Crimp Wire Connectors

Crimp wire connectors function by physically compressing (crimping) a metal barrel to encase and hold wire ends. This process is generally executed using a specialized crimping tool that exerts the right amount of pressure to deform the barrel, ensuring a tight mechanical bond between the connector and the wire. The crimping action establishes both an electrical and mechanical connection, making it one of the most durable methods of wire connection.

Advantages and Disadvantages of Crimp Wire Connectors

Advantages:

- Durability: The crimping process offers a robust mechanical bond, ensuring the connection remains intact even in challenging environments.

- Variety: These types of wire connectors come in various shapes and sizes, including rings, spades, and butt connectors, catering to different application needs.

- Low Electrical Resistance: Due to the tight bond, crimp connectors maintain low electrical resistance, ensuring efficient current flow.

Disadvantages:

- Requires Specialized Tool: To achieve the desired connection, a crimping tool is essential. The quality of the crimp can vary based on the tool’s quality.

- Permanent Connection: Unlike some connectors, crimped connections are generally permanent. While this can be an advantage in certain situations, it can also be a limitation if changes or adjustments are needed.

- Skill-Dependent: The quality of the connection depends significantly on the user’s skill. A poorly crimped connector might not provide a reliable connection.

Use Cases of Crimp Wire Connectors

- Automotive Wiring: Due to their durability and resistance to vibrations, crimp connectors are widely used in vehicle wiring systems.

- Marine Applications: In marine environments where conditions can be corrosive and wet, the reliability of crimp connectors makes them a preferred choice.

- Home Electronics: For connections inside devices like speakers, radios, or other household electronics, crimp connectors provide a solid and long-lasting bond.

- Industrial Wiring: In industrial setups with heavy machinery and high vibrations, the robust nature of crimped connections ensures system integrity.

Understanding the fundamentals and applications of crimp wire connectors empowers professionals and DIY enthusiasts alike to make informed choices, optimizing both the safety and efficiency of their electrical projects.

Types of Wire Connectors: 4. Terminal Blocks

Working Principle of Terminal Blocks

Terminal blocks, often referred to as terminal strips or connection blocks, are modular blocks that facilitate the connection of multiple wires without them being in direct contact with each other. Each wire is connected to a specific terminal on the block using a screw or clamp mechanism. The terminals are then internally connected in a specific configuration (like series, parallel, or busbar) depending on the block’s design. This design allows for organized distribution and grouping of electrical connections within a system.

Advantages and Disadvantages of Terminal Blocks

Advantages:

- Organization: These types of write connectors are perfect for consolidating and organizing multiple wire connections, especially in complex electrical systems.

- Versatility: They are available in various configurations and sizes to accommodate different connection needs and wire gauges.

- Ease of Maintenance: Since each wire is connected to its own individual terminal, it’s easier to troubleshoot, replace, or modify specific connections without disturbing the entire setup.

Disadvantages:

- Size Constraint: Terminal blocks can be bulkier than other types of connectors, making them less ideal for confined spaces.

- Installation Time: Setting up a terminal block might take longer compared to other connectors, especially when dealing with numerous wire connections.

- Potential for Loosening: Over time, screws or clamps might loosen due to vibrations or temperature fluctuations, requiring periodic checks and retightening.

Use Cases of of Terminal Blocks

- Control Panels: Terminal blocks are a mainstay in electrical control panels, where they help organize and distribute multiple connections efficiently.

- Industrial Machinery: In machines with complex wiring, terminal blocks streamline connections and simplify maintenance tasks.

- Home Circuit Breakers: They can be found in residential electrical setups, helping manage and distribute household electrical circuits.

- Telecommunication Equipment: Terminal blocks are used to manage and organize the myriad of connections within telecom setups.

Terminal blocks, with their structured and modular design, offer an effective solution for managing multiple electrical connections, ensuring both system integrity and ease of maintenance in a variety of applications.

Types of Wire Connectors: 5. Fork Connectors (Spade Terminals)

Working Principle of Fork Connectors

The fifth among the common types of wire connectors, fork connectors, or spade terminals, are characterized by their forked shape, which allows them to be easily connected or disconnected from a screw or stud terminal. The wire is typically crimped or soldered to the other end of the spade. The fork design permits easy insertion under a screw head or into terminal blocks without entirely removing the screw, making both installation and removal swift and hassle-free.

Advantages and Disadvantages of Fork Connectors

Advantages:

- Quick Installation and Removal: The unique fork design facilitates rapid attachment and detachment without the need to completely remove screws or bolts.

- Versatile Applications: Spade terminals are available in various sizes and gauges, making them compatible with numerous applications.

- Secure Connection: Once tightened under a screw or stud, they provide a reliable and firm connection, ensuring consistent electrical continuity.

Disadvantages:

- Potential for Slippage: If not securely tightened, there’s a possibility for the connector to slip out, especially in vibrating environments.

- Not Ideal for High-Tension Applications: Due to their design, they might not be the best choice for applications where the wire is subjected to pulling or tugging forces.

- Exposure to Elements: Unlike some enclosed connectors, the connection point can be exposed to external elements, making them less ideal for corrosive or moist environments unless specifically designed for such conditions.

Use Cases of Fork Connectors

- Electrical Panels: Their ease of installation makes them a popular choice in electrical panels where connections might need frequent checks or changes.

- Automotive Wiring: Spade terminals are frequently used in vehicle electronics, such as connecting accessories, lights, or sound systems.

- Home Appliances: Many household appliances with removable components utilize spade terminals for easy assembly and maintenance.

- Audio Systems: They can be found in sound systems, connecting speakers to amplifiers or receivers, allowing for swift component swaps or upgrades.

Fork connectors or spade terminals offer a blend of convenience and reliability, making them a preferred choice in various scenarios where ease of connection and disconnection is a priority.

Table of Comparison for 5 Types of Wire Connectors

| Wire Connector Type | Primary Feature | Ease of Use | Advantages | Disadvantages | Use Case |

| Twist-On Wire Connectors (Wire Nuts) | Spiral threading for wire twisting | Moderate | Secure connection; No special tools required | Not suitable for high-vibration environments; May loosen over time | General home wiring; Junction boxes; Light fixtures |

| Push-In Wire Connectors | Spring-loaded clamp for push-to-connect | Easy | Fast installation; Compact design; Uniform connection quality | Can be challenging to remove; Depends on wire quality | Modern electrical installations; Circuit boards; Lighting |

| Crimp Wire Connectors | Metal barrel for crimping | Moderate (requires tool) | Durable; Low electrical resistance; Wide variety | Permanent connection; Skill-dependent | Automotive wiring; Marine applications; Home electronics |

| Terminal Blocks | Modular blocks for organized connections | Moderate | Organized wiring; Versatile configurations; Easy maintenance | Bulkier; Installation time; Potential for loosening | Control panels; Industrial machinery; Home circuit breakers |

| Fork Connectors (Spade Terminals) | Fork design for screw terminals | Easy | Quick installation and removal; Secure connection | Potential for slippage; Exposure to elements | Electrical panels; Automotive wiring; Home appliances; Audio systems |

This table offers a brief and direct comparison of the primary features, ease of use, durability, and ideal scenarios for the five types of wire connectors. Professionals and hobbyists can reference this table to quickly determine the most suitable connector type for their specific project needs.

Conclusion

Choosing the right type of wire connector is paramount in ensuring the safety, efficiency, and longevity of any electrical connection. With the myriad of options available, understanding the distinct types of wire connectors and their unique advantages and use cases becomes a critical knowledge asset for both professionals and DIY enthusiasts. Whether you’re working on a small household project or a large-scale industrial installation, aligning your choice with the specific requirements of the task can significantly enhance the outcome.

As technology and design evolve, it’s essential to stay updated, but the foundational understanding of these connectors will undoubtedly remain a cornerstone in the electrical domain. If you liked this guide, check out our article on 8 types of multivibrators and their use cases.

Frequently Asked Questions (FAQs)

- What are the primary types of wire connectors used in electrical projects?

There are several types of wire connectors available, each suited for specific applications. The core types discussed in this post include Twist-On Wire Connectors (Wire Nuts), Push-In Wire Connectors, Crimp Wire Connectors, Terminal Blocks, and Fork Connectors (Spade Terminals). - Which types of wire connectors are best for quick installations or frequent adjustments?

Push-In Wire Connectors and Fork Connectors (Spade Terminals) are generally preferred for quick installations and adjustments due to their easy-to-use design. - How do I determine the most suitable wire connector type for my project?

It’s essential to consider factors like the environment (e.g., moisture, vibrations), the number of wires you’re connecting, and whether the connection needs to be permanent or adjustable. This blog post provides a comparison table highlighting the advantages and ideal scenarios for different types of wire connectors, which can guide your decision. - Are there any safety concerns associated with using specific types of wire connectors?

While all wire connectors are designed with safety in mind, it’s vital to ensure proper installation and regular maintenance checks, especially in environments with temperature fluctuations or vibrations. Always choose the connector type best suited for the specific conditions of your project to ensure maximum safety.