Types of Isolators – In the field of electrical engineering, isolators play a crucial role in ensuring the safety and reliability of power systems. These essential devices are designed to disconnect electrical circuits from their power source, providing an effective way to isolate and protect equipment, personnel, and the public from potential electrical hazards. In this article, we will delve into the various types of isolators and their significance in maintaining a safe and efficient electrical infrastructure.

What is an Electrical Isolator?

An electrical isolator, also known as a disconnect switch or isolating switch, is a vital component of an electrical system that is designed to disconnect a specific part of the circuit from the rest of the electrical network. Its primary function is to provide a visible gap in the circuit, effectively isolating a section of the electrical equipment or transmission line from the power source or other connected components.

Electrical isolators play a crucial role in ensuring the safety and efficiency of power systems. They are widely used in various applications, including power distribution networks, substations, industrial installations, and high-voltage transmission lines. The key purpose of an electrical isolator is to provide a means for personnel to safely perform maintenance, repairs, or inspections on electrical equipment without being exposed to hazardous electrical currents.

Here are some important characteristics and functions of electrical isolators:

- Disconnection Capability: Electrical isolators are designed to open and close circuits manually or automatically. When in the open position, they create a visible air gap in the electrical path, preventing the flow of current.

- Visible Break: One critical feature of isolators is that they provide a visible indication of their open or closed status. This visibility ensures that maintenance personnel can verify that the circuit is indeed disconnected and safe to work on.

- Mechanical Operation: In most cases, isolators are operated manually, using a handle or lever. However, motorized isolators are also available, allowing remote operation for added convenience and safety.

- No Load-Breaking Capacity: Unlike circuit breakers, electrical isolators are not intended to interrupt the flow of current during fault conditions. Their primary purpose is to provide a safe disconnection point.

- Safety Precautions: Electrical isolators are often equipped with safety interlocks to prevent accidental operation or opening under load, as such an action could lead to electrical arcing and damage to the isolator.

- Ratings: Electrical isolators come in various sizes and ratings, suitable for different voltage and current levels, ranging from low voltage in industrial settings to high voltage in transmission systems.

Overall, electrical isolators are essential components in electrical systems, providing a crucial safety barrier that enables maintenance and repair work on electrical equipment without posing risks to personnel or the surrounding environment. Their reliable operation and ability to isolate electrical circuits when needed make them indispensable elements in the efficient and secure operation of power systems.

Different Types of Electrical Isolators

Electrical isolators, also known as disconnect switches, come in various types to suit different applications and voltage levels. Here are some common types of electrical isolators:

- Load Break Switches (LBS)

- Isolating Switches

- Circuit Breakers

- Earth Switches (Grounding Switches)

- Motorized Isolators

- Pantograph Isolators

- Rotary Isolators

- Gas-insulated Disconnectors

- Center Break Disconnectors

- Double Break Disconnectors

Each type of electrical isolator serves specific purposes and is chosen based on factors such as voltage levels, application requirements, and safety considerations. Proper selection and installation of isolators are essential to ensure the safe operation and maintenance of electrical systems.

Load Break Switches (LBS)

Load Break Switches (LBS), also known as disconnect switches or isolating switches, are indispensable components in power distribution networks and industrial installations. These essential devices play a critical role in enhancing electrical safety, improving system reliability, and enabling efficient maintenance operations. In this article, we will delve into the functionalities, applications, and benefits of Load Break Switches.

Functionality and Operation

Load Break Switches are designed to provide a means of manually or remotely opening and closing electrical circuits. They allow for the disconnection of loads or sections of the electrical system from the main power supply. When in the open position, LBS creates a visible gap in the circuit, effectively breaking the electrical connection and stopping the flow of current. This disconnection capability is particularly valuable during maintenance, repair work, and emergencies, as it ensures the safety of personnel and equipment.

Types of Load Break Switches

There are various types of Load Break Switches, each catering to specific applications and voltage levels. Some common types include:

- Air-Break Switches: These switches use air as the insulating medium to break the electrical circuit.

- Oil-Break Switches: Oil is used as the insulating medium, providing effective arc extinction when breaking the circuit.

- Vacuum-Break Switches: Vacuum-Break Switches use a vacuum as the insulating medium, offering reliable and efficient arc quenching.

- SF6 (Sulfur Hexafluoride) Load Break Switches: These switches utilize SF6 gas, providing excellent dielectric properties and arc extinction capabilities.

Applications of Load Break Switches

Load Break Switches find application in various electrical systems, including:

- Power Distribution Networks: LBS are commonly used in distribution networks to isolate faulty sections, allowing for easier fault detection and quicker restoration of power.

- Ring Main Units (RMUs): RMUs are compact, self-contained units used in secondary distribution networks. Load Break Switches are often integrated into RMUs to facilitate sectionalization and quick isolation of faulty segments.

- Substations: In substations, Load Break Switches are employed to disconnect transformers, capacitors, and other equipment for maintenance purposes.

- Industrial Installations: LBS are utilized in industrial settings to isolate motors, generators, and other electrical equipment during servicing.

Benefits of Load Break Switches

The advantages of Load Break Switches include:

- Enhanced Safety: Load Break Switches provide a clear visual indication of the disconnection status, reducing the risk of accidental contact with live circuits during maintenance or repair work.

- Reduced Downtime: By facilitating quick isolation of faulty sections, LBS helps minimize downtime and improve system reliability.

- Remote Operation: Motorized Load Break Switches enable remote operation, allowing for safer and more convenient disconnection of circuits from a control room.

- Simplified Maintenance: Load Break Switches streamline maintenance procedures, as they offer easy access to equipment for inspection and repairs.

Isolating Switches

Isolating switches, also known as disconnect switches or isolation switches, are fundamental components in electrical engineering that play a crucial role in ensuring the safety and efficiency of power systems. These specialized switches are designed to provide a visible gap in the electrical circuit, effectively disconnecting specific sections of the system from the main power source. In this article, we will explore the functionalities, applications, and benefits of isolating switches.

Functionality and Operation

Isolating switches serve as dedicated devices for the sole purpose of isolating electrical circuits. Unlike circuit breakers, they do not actively interrupt the flow of current during fault conditions. Instead, their primary function is to create a visible break in the circuit, allowing for safe maintenance, repair, or inspection of electrical equipment without exposing personnel to hazardous electrical currents.

Types of Isolating Switches

Various types of isolating switches are available, each designed to suit different applications and voltage levels. Some common types include:

- Rotary Isolating Switches: These switches use a rotary mechanism to disconnect electrical circuits manually.

- Knife Switches: Knife switches consist of a pivoting metal blade that can be moved to create an open or closed circuit.

Center Break Disconnectors: Center break disconnectors have a central gap, allowing both sides of the switch to open, effectively isolating the circuit. - Double Break Disconnectors: Double break disconnectors have two breaks in the current path, providing redundancy and improved safety during the isolation process.

Applications of Isolating Switches

Isolating switches find widespread application in various electrical systems, including:

- Power Distribution Networks: These are employed in substations and distribution networks to isolate faulty equipment or sections of the network during maintenance or repair work.

- Industrial Installations: In industrial settings, isolating switches are used to disconnect motors, generators, and other electrical devices for maintenance and safety purposes.

- Testing and Measurement: Isolating switches are utilized in testing and measurement setups to isolate instruments or circuits during specific procedures.

Benefits of Isolating Switches

The advantages of isolating switches include:

- Enhanced Safety: Isolating switches provide a clear visual indication of the open or closed status, reducing the risk of accidental contact with live circuits during maintenance or repair work.

- Convenience in Maintenance: By creating a visible gap in the circuit, isolating switches makes it easier and safer for personnel to access electrical equipment for inspection and repairs.

- Protection for Personnel: Isolating switches protect maintenance personnel from exposure to hazardous electrical currents, reducing the likelihood of electrical accidents.

Circuit Breakers

Circuit breakers are essential safety devices that form the backbone of modern electrical systems. These automatic switches play a critical role in protecting electrical circuits and equipment from overcurrents, short circuits, and other electrical faults. Their ability to interrupt the flow of current swiftly and safely makes them vital components in power distribution networks, industrial installations, residential buildings, and various other applications. In this article, we will explore the functionalities, types, and significance of circuit breakers in ensuring the reliability and safety of electrical systems.

Functionality and Operation

The primary function of circuit breakers is to automatically interrupt the flow of electrical current when a fault is detected in the circuit. This fault could be an overcurrent due to excessive load or a short circuit caused by a fault in the electrical system. By opening the circuit, circuit breakers prevent damage to equipment, wiring, and other components, as well as reduce the risk of electrical hazards such as fires and electrical shocks.

Types of Circuit Breakers

Circuit breakers come in various types, each tailored to specific applications and voltage levels. Some common types include:

- Air Circuit Breakers (ACBs): ACBs use air as the arc extinguishing medium to interrupt the current flow. They are commonly used in low to medium-voltage applications.

- Molded Case Circuit Breakers (MCCBs): MCCBs are typically used for lower voltage applications and are housed in a molded case, providing better insulation and protection.

- Miniature Circuit Breakers (MCBs): MCBs are commonly used in residential and commercial buildings to protect electrical circuits from overload and short circuits.

- Residual Current Circuit Breakers (RCCBs): RCCBs, also known as ground fault circuit interrupters (GFCIs), are designed to protect against electrical leakage and ground faults, enhancing safety in wet or damp environments.

Trip Units and Protection Coordination

Circuit breakers are equipped with trip units that monitor the current passing through the circuit. When the current exceeds a predetermined threshold, the trip unit activates, causing the circuit breaker to open and disconnect the faulty circuit. Protection coordination is a critical aspect of circuit breaker applications, ensuring that the most appropriate breaker trips first during a fault, minimizing disruptions, and maximizing system reliability.

Importance of Circuit Breakers

Circuit breakers offer several crucial benefits:

- Overcurrent Protection: Circuit breakers safeguard electrical equipment from damage by preventing excessive current flow.

- Fire Prevention: By interrupting fault currents, circuit breakers mitigate the risk of electrical fires caused by overloaded circuits or short circuits.

- Electrical Safety: Circuit breakers protect individuals from electrical shocks by quickly disconnecting faulty circuits.

- System Reliability: Properly coordinated circuit breakers enhance the reliability and stability of electrical systems, reducing downtime and enhancing productivity.

Earth Switches (Grounding Switches)

Earth switches, also known as grounding switches or ground switches, are critical components in electrical systems that play a vital role in ensuring the safety of personnel and equipment during maintenance and fault-handling procedures. These specialized switches are designed to connect or disconnect electrical equipment from the ground (earth), effectively grounding the equipment to provide a safe path for fault currents. In this article, we will explore the functionalities, applications, and significance of earth switches in enhancing electrical safety.

Functionality and Operation

The primary function of earth switches is to provide a direct and low-resistance path to the ground for fault currents. In normal operation, electrical equipment is connected to the power supply, and the earth switch remains open, isolating the equipment from the ground. However, during maintenance or when a fault occurs, the earth switch is closed, creating a low-resistance path to the ground. This action allows any fault currents to safely flow to the ground, effectively isolating the faulty section of the electrical system and preventing electric shock hazards.

Applications of Earth Switches

Earth switches find application in various electrical systems, including:

- Substations: In high-voltage substations, earth switches are used to ground transformers, circuit breakers, and other equipment during maintenance or emergencies.

- Transmission Lines: Earth switches are employed in transmission line towers to provide a safe grounding path for lightning currents and protect the equipment from damage.

- Switchyards and Switchgear: Earth switches are integrated into switchyards and switchgear assemblies to provide a safe grounding mechanism for disconnecting switches and other equipment.

Safety Interlocks

To prevent accidental operations and ensure proper safety protocols, earth switches often come equipped with safety interlocks. These interlocks ensure that the earth switch can only be closed when the associated equipment is properly isolated from the power supply. Likewise, the earth switch cannot be opened when there is a live voltage present in the equipment, avoiding potential accidents due to human error.

Importance of Earth Switches

The significance of earth switches lies in their contribution to electrical safety and system reliability:

- Electrical Safety: Earth switches protect maintenance personnel from the risk of electric shock by safely diverting fault currents to the ground during maintenance activities.

- Equipment Protection: By grounding the equipment during fault conditions, earth switches prevent damage to electrical components and devices, reducing downtime and maintenance costs.

- Lightning Protection: In transmission lines and substations, earth switches help dissipate lightning-induced currents, protecting the equipment from transient overvoltages.

Motorized Isolators

Motorized isolators, also known as motor-operated isolators or motorized disconnect switches, are specialized electrical switches equipped with electric motors that allow for remote operation. These innovative devices provide a convenient and safe way to disconnect electrical circuits or equipment from the power source without manual intervention. Motorized isolators are widely used in a variety of applications, ranging from power distribution networks to industrial installations, where enhanced safety and remote control are essential. In this article, we will explore the functionalities, benefits, and applications of motorized isolators.

Remote Operation and Control

The distinguishing feature of motorized isolators is their ability to be operated remotely. Instead of relying on manual intervention to open or close the switch, motorized isolators can be controlled from a distance using control panels, SCADA systems, or other remote control mechanisms. This capability makes them ideal for applications where human intervention may be impractical or hazardous.

Functionality and Operation

Motorized isolators function similarly to regular isolating switches, providing a visible gap in the electrical circuit when in the open position. They offer the same safety benefits of isolating electrical circuits during maintenance, repair, or inspection work, ensuring the safety of personnel and equipment. The motorized operation enables the switch to be controlled remotely, providing added convenience and safety during disconnection procedures.

Applications of Motorized Isolators

Motorized isolators find a wide range of applications, including:

- Power Distribution Networks: In substations and power distribution networks, motorized isolators are used to disconnect transformers, capacitors, and other equipment for maintenance and safety.

- Industrial Installations: Motorized isolators are employed in industrial settings to isolate motors, generators, and other electrical equipment during servicing or emergencies.

- Renewable Energy Systems: In solar power plants and wind farms, motorized isolators are used to disconnect renewable energy sources from the grid during maintenance or grid faults.

- Remote Locations: In locations with limited accessibility, such as offshore platforms or remote facilities, motorized isolators offer the convenience of remote control for disconnection and reconnection procedures.

Benefits of Motorized Isolators

Motorized isolators offer several advantages that contribute to improved safety and efficiency:

- Enhanced Safety: The ability to control the isolator remotely reduces the need for personnel to be physically present near the equipment during disconnection, reducing the risk of electrical accidents.

- Convenience and Time Savings: Remote operation allows for quicker disconnection and reconnection procedures, saving time and improving maintenance efficiency.

- Integration with Automation Systems: Motorized isolators can be easily integrated into automation and control systems, enabling seamless operation and monitoring of electrical circuits.

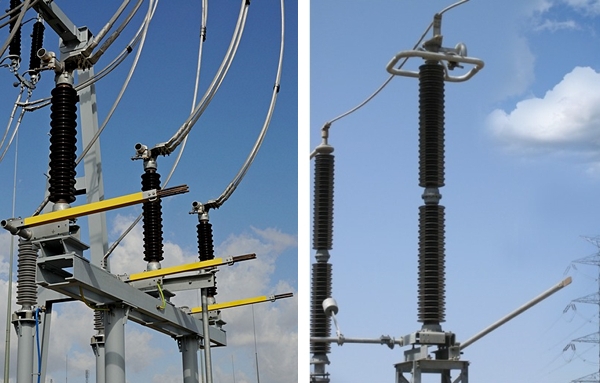

Pantograph Isolators

Pantograph isolators, also known as pantograph disconnectors or simply pantographs, are specialized electrical switching devices used in high-voltage transmission systems. These sophisticated isolators play a crucial role in isolating and disconnecting high-voltage lines and equipment, ensuring the safety of personnel and equipment during maintenance, repair, or emergencies. The unique design and functionality of pantograph isolators make them ideal for handling heavy electrical loads in demanding transmission environments. In this article, we will explore the functionalities, advantages, and applications of pantograph isolators.

Design and Mechanism

Pantograph isolators are named after their mechanical linkage, which resembles the pantograph mechanism used in some train systems. This mechanical linkage allows multiple contacts or blades to move simultaneously, ensuring a synchronized and reliable disconnection process. The pantograph mechanism is particularly useful in high-voltage applications, as it can handle heavy electrical loads with precision.

Functionality and Operation

The primary function of pantograph isolators is to provide a visible air gap in the electrical circuit when open, effectively isolating the section of the transmission line or equipment from the power source. When closed, they securely reconnect the circuit, allowing for the flow of electricity. Pantograph isolators are manually operated, and their unique linkage ensures that all contacts move in unison, providing a smooth and reliable disconnection process.

Applications of Pantograph Isolators

Pantograph isolators find prominent applications in high-voltage transmission systems, including:

- Transmission Lines: In overhead transmission lines, pantograph isolators are used to isolate segments of the line for maintenance or repair work.

- Substations: They are also employed in substations to isolate high-voltage equipment, such as transformers and circuit breakers, during maintenance and emergency scenarios.

Advantages of Pantograph Isolators

Pantograph isolators offer several advantages that make them ideal for high-voltage applications:

- Precision and Synchronization: The pantograph mechanism ensures synchronized movement of contacts, minimizing the risk of partial disconnection and arc formation.

- Heavy Load Capacity: Pantograph isolators can handle high electrical loads, making them suitable for large-scale transmission systems.

- Visual Verification: The visible air gap in the open position provides a clear indication of the disconnection status, enabling safe maintenance procedures.

Safety Considerations

Safety is paramount when dealing with high-voltage systems, and pantograph isolators are designed with specific safety features. These features may include grounding switches, safety interlocks, and clear warning labels to prevent accidental operations and protect maintenance personnel.

Rotary Isolators

Rotary isolators, also known as rotary disconnect switches or rotary switches, are specialized electrical switches that provide a straightforward and efficient method for disconnecting electrical circuits. These switches use a rotary mechanism to create a visible gap in the circuit, effectively isolating specific sections of the electrical system from the power source. Rotary isolators are widely used in various applications, ranging from industrial installations to power distribution networks, where reliable disconnection is essential for maintenance, safety, and repair operations. In this article, we will explore the functionalities, advantages, and applications of rotary isolators.

Rotary Mechanism and Operation

The defining feature of rotary isolators is their rotary mechanism, which allows for manual disconnection of electrical circuits. When operated, the rotary switch moves the contact or blade to a position that opens the circuit, creating a visible gap between the contacts. This visible gap provides a clear indication that the circuit is disconnected, ensuring the safety of maintenance personnel and preventing accidental contact with live electrical components.

Functionality and Safety Features

Rotary isolators serve as dedicated devices for isolating electrical circuits. Unlike circuit breakers, they do not actively interrupt the current flow during fault conditions. Instead, their primary function is to provide a visible break in the circuit to facilitate safe maintenance and repair work. Many rotary isolators are equipped with safety features such as padlocking provisions and interlocking mechanisms to prevent unauthorized or accidental operations.

Applications of Rotary Isolators

Rotary isolators find a wide range of applications, including:

- Industrial Installations: In industrial settings, rotary isolators are commonly used to isolate motors, generators, and other electrical equipment during maintenance and repair activities.

- Power Distribution Networks: In substations and power distribution networks, rotary isolators are employed to disconnect transformers, circuit breakers, and other equipment for maintenance and safety.

- Switchyards and Switchgear: Rotary isolators are integrated into switchyards and switchgear assemblies to provide a safe isolation mechanism for disconnecting switches and other equipment.

Advantages of Rotary Isolators

Rotary isolators offer several advantages that contribute to their widespread use:

- Simple and Reliable Operation: The rotary mechanism provides a straightforward and reliable disconnection process, ensuring the safe isolation of electrical circuits.

- Visible Disconnection Status: The visible gap in the open position offers a clear indication that the circuit is disconnected, promoting safety during maintenance operations.

- Durability: Rotary isolators are designed to withstand frequent operations and harsh environmental conditions, making them suitable for a variety of applications.

Safety Considerations

Safety is of utmost importance when dealing with electrical isolation, and rotary isolators are designed with specific safety features to prevent accidents. These may include padlocking provisions, interlocks to prevent opening under load, and visible labels to indicate the switch’s status.

Gas-insulated Disconnectors

Gas-insulated disconnectors, also known as gas-insulated disconnect switches or gas-insulated isolators, are specialized electrical switching devices that utilize gas insulation to provide efficient and reliable electrical isolation. These innovative disconnectors are widely used in high-voltage applications, such as gas-insulated substations (GIS) and other high-voltage installations, where space is limited, and superior dielectric properties are required. Gas-insulated disconnectors offer several advantages over conventional air-insulated disconnectors, making them essential components in modern high-voltage electrical systems. In this article, we will explore the functionalities, benefits, and applications of gas-insulated disconnectors.

Gas Insulation and Operation

Gas-insulated disconnectors use insulating gas, such as sulfur hexafluoride (SF6), as the dielectric medium. SF6 gas has excellent insulating properties, enabling the design of compact and efficient disconnectors that can withstand high voltage and heavy electrical loads. When the disconnector is in the open position, the contacts are separated, creating a visible air gap and isolating the electrical circuit. When closed, the contacts are connected, allowing current to flow through the circuit.

Functionality and Efficiency

Gas-insulated disconnectors provide reliable electrical isolation with minimal maintenance requirements. The use of gas insulation offers numerous benefits, including reduced insulation distance, a smaller footprint, and enhanced safety. These disconnectors are designed to handle heavy electrical loads, making them suitable for demanding high-voltage applications.

Applications of Gas-insulated Disconnectors

Gas-insulated disconnectors find prominent applications in various high-voltage installations, including:

- Gas-insulated Substations (GIS): Gas-insulated disconnectors are a fundamental component of GIS, where they play a crucial role in isolating circuit breakers, transformers, and other high-voltage equipment during maintenance and repair operations.

- High-Voltage Transmission Systems: In high-voltage transmission lines, gas-insulated disconnectors are used to isolate and disconnect sections of the line for maintenance and repair purposes.

Advantages of Gas-insulated Disconnectors

Gas-insulated disconnectors offer several advantages over conventional air-insulated disconnectors:

- Compact Design: Gas-insulated disconnectors have a more compact design, allowing for space-saving installations, which is particularly beneficial in GIS installations.

- Enhanced Dielectric Properties: The insulating gas, SF6, provides superior dielectric strength, allowing for reduced insulation distances and improved electrical isolation.

- Minimal Maintenance: Gas-insulated disconnectors require less maintenance compared to air-insulated disconnectors, reducing operational costs and downtime.

Environmental Considerations

While SF6 gas provides excellent insulating properties, it is also known to be a potent greenhouse gas with a high global warming potential. Proper handling and management of SF6 gas are crucial to minimize its environmental impact. Many efforts are being made to explore eco-friendly alternatives to SF6 in high-voltage applications.

Center Break Disconnectors

Center break disconnectors, also known as center break isolators or center break switches, are specialized electrical switches designed with a central gap in the middle. These innovative disconnectors offer dual breaking points, providing enhanced reliability and safety in electrical isolation. Center break disconnectors are widely used in various high-voltage applications, including substations and transmission systems, where efficient and secure electrical isolation is essential for maintenance and safety. In this article, we will explore the functionalities, advantages, and applications of center break disconnectors.

Design and Operation

The distinguishing feature of center break disconnectors is their unique design with a central gap or break. The switch’s contacts are divided into two parts, creating two break points in the electrical circuit. When the disconnector is in the open position, both sides of the contacts move away from each other, creating a visible air gap in the center. This design offers enhanced isolation performance and allows for a more reliable breaking operation, reducing the risk of partial disconnection or arcing.

Functionality and Safety Features

Center break disconnectors function similarly to other isolators, providing a visible air gap in the open position to indicate that the electrical circuit is isolated. These disconnectors are manually operated, allowing for straightforward and precise control over the disconnection process. Many center break disconnectors come equipped with safety features, such as interlocking mechanisms, to prevent accidental operations and ensure proper safety protocols.

Applications of Center Break Disconnectors

Center break disconnectors find various applications in high-voltage installations, including:

- Substations: In substations, center break disconnectors are commonly used to isolate high-voltage equipment, such as transformers, circuit breakers, and busbars, for maintenance and safety.

- Transmission Systems: Center break disconnectors are employed in transmission lines and switchyards to disconnect segments of the transmission system during maintenance and repair work.

Advantages of Center Break Disconnectors

Center break disconnectors offer several advantages that make them valuable in high-voltage applications:

- Enhanced Reliability: The dual breaking points provided by the center gap design ensure a more reliable disconnection process, reducing the risk of partial disconnection and arc formation.

- Clear Visual Indication: The central gap creates a visible air break, offering a clear indication of the disconnection status, enhancing safety during maintenance operations.

- Improved Safety: Center break disconnectors are designed with safety considerations, including interlocking mechanisms and safety labels, to prevent accidental operations and protect maintenance personnel.

Safety Considerations

Safety is paramount when dealing with high-voltage electrical systems, and center break disconnectors are designed with specific safety features to prevent accidents. Interlocking mechanisms, padlocking provisions, and clear warning labels are among the safety considerations integrated into these disconnectors.

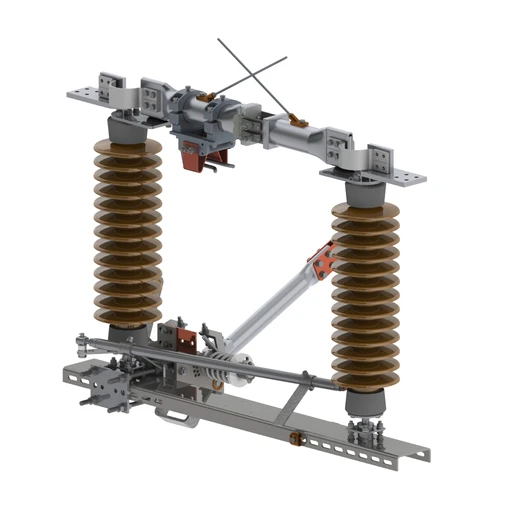

Double Break Disconnectors

Double-break disconnectors, also known as double-break isolators or double-break switches, are specialized electrical switches designed with two breaks in the current path. These innovative disconnectors provide redundancy and improved safety in electrical isolation by offering two visible air gaps when in the open position. Double break disconnectors are widely used in various high-voltage applications, including substations and power transmission systems, where reliable and secure electrical isolation is crucial for maintenance, repair, and safety. In this article, we will explore the functionalities, advantages, and applications of double-break disconnectors.

Design and Operation

Double break disconnectors are designed with two breaks in the current path, providing two visible air gaps when the switch is open. This unique design ensures redundancy in the electrical isolation process, reducing the risk of partial disconnection or arcing. The contacts are spaced apart to create two isolated gaps, enhancing the reliability and safety of the disconnection process.

Functionality and Safety Features

Similar to other isolators, double break disconnectors provide a visible air gap in the open position, indicating that the electrical circuit is disconnected. These disconnectors are manually operated, allowing for precise control over the disconnection process. Many double-break disconnectors are equipped with safety features, such as interlocking mechanisms and padlocking provisions, to prevent accidental operations and ensure the safety of maintenance personnel.

Applications of Double Break Disconnectors

Double break disconnectors find applications in various high-voltage installations, including:

- Substations: In substations, double break disconnectors are commonly used to isolate high-voltage equipment, such as transformers, circuit breakers, and busbars, for maintenance and safety.

- Transmission Systems: Double break disconnectors are employed in power transmission systems, switchyards, and substations to disconnect segments of the transmission line during maintenance and repair work.

Advantages of Double Break Disconnectors

Double break disconnectors offer several advantages that make them valuable in high-voltage applications:

- Redundancy: The dual breaks in the current path provide redundancy in the disconnection process, reducing the risk of partial disconnection and enhancing the overall reliability of the isolator.

- Enhanced Safety: Double break disconnectors are designed with safety features to prevent accidental operations, ensuring the safety of maintenance personnel during disconnection procedures.

- Visible Indication: The two visible air gaps offer a clear indication of the disconnection status, promoting safety during maintenance operations.

Safety Considerations

Safety is of paramount importance when dealing with high-voltage electrical systems, and double-break disconnectors are designed with specific safety features to prevent accidents. Interlocking mechanisms, padlocking provisions, and visible warning labels are among the safety considerations integrated into these disconnectors.

Conclusion

Isolators are vital components in electrical systems, serving to disconnect and isolate circuits for maintenance and safety. Different types, such as electrical isolators, load break switches, motorized isolators, gas-insulated disconnectors, pantograph isolators, center break disconnectors, and double break disconnectors, cater to various applications and offer distinct advantages. They enhance safety through visible disconnection status, provide remote control capabilities, and ensure reliable power distribution. Understanding and using the right isolator for specific applications is crucial for maintaining electrical infrastructure and safeguarding personnel from hazards, ensuring uninterrupted electricity supply in modern systems.

FAQs about Types of Isolators

1. What are the different types of isolators used in electrical systems?

There are various types of isolators, including electrical isolators, load break switches (LBS), motorized isolators, gas-insulated disconnectors, pantograph isolators, center break disconnectors, and double break disconnectors.

2. How do isolators enhance electrical safety?

Isolators provide a visible gap in the circuit when open, isolating specific sections of the system for maintenance or repair work. This visible gap ensures that personnel can safely work on electrical equipment without exposure to live currents.

3. What are the applications of motorized isolators?

Motorized isolators are used in applications where remote operation and control are required. They enable efficient and safe disconnection of electrical circuits from a distance, reducing the need for manual intervention.

4. What advantages do gas-insulated disconnectors offer over air-insulated disconnectors?

Gas-insulated disconnectors use insulating gas like SF6, which provides superior dielectric properties and allows for a more compact design. This makes them suitable for high-voltage applications with limited space.

5. How do center break disconnectors and double break disconnectors differ in functionality?

Center break disconnectors have a central gap, creating two contacts on either side, while double break disconnectors have two gaps, providing two breaking points. Double break disconnectors offer enhanced redundancy in electrical isolation compared to center break disconnectors.