Fuses play a vital role in maintaining electrical safety across a wide range of settings, from household appliances to industrial machinery, much like the Types of Electrical Panels and types of circuit breakers within Electrical Infrastructure. These small but crucial components act as the guardians of electrical circuits, protecting them from overcurrent and potential hazards. With various types of fuses available, each designed for specific applications and electrical demands, understanding their differences is key to ensuring the right fuse is used for the right application.

In this comprehensive guide, we will explore the different types of fuses, from rapid-response ultra-rapid fuses to specialized striker and Type F fuses. We’ll delve into their working principles, advantages, disadvantages, and typical use cases. This knowledge is essential not only for professionals in the electrical field but also for anyone looking to enhance their understanding of electrical safety, similar to understanding types of electrical outlets or types of alarm systems. Join us as we navigate the intricate world of fuses, a critical component in safeguarding electrical systems.

What is a Fuse?

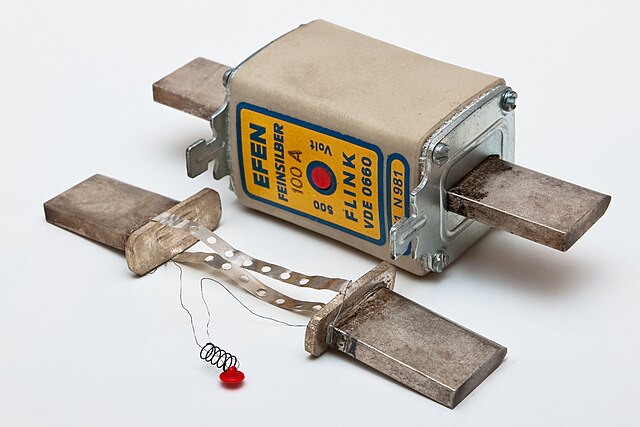

Fuses are a type of security measure used in electrical systems to protect the appliances and the whole circuit from sudden surges in current. When there is a current surge, the fuse “blows,” tripping the circuit and cutting off the current. Just at what point the fuse blows depends on its breaking capacity and that usually depends on the types of fuses we are talking about.

19 Types of Fuses

19 main Types of Fuses include:

- Ultra-Rapid, Fast Acting, and Slow Acting Fuses

- AC and DC Fuses

- Cylindrical and HRC Fuse Types

- Car Fuses (Blade, Bolt-Down, and Cartridge Fuses)

- Bolted Tag, Bottle, and Cartridge Fuses

- Centred Tag, Offset Tag, and Slotted Tag Fuses

- Thermal and SMD Fuses

- Striker, Type C, D, and F Fuses

Types of Fuses: Ultra-Rapid, Fast Acting, and Slow Acting Fuses

Working Principles of Different Fuse Speeds

The fuse speed refers to how quickly a fuse responds to overcurrent. Ultra-rapid fuses, also known as Very Fast Acting or High-Speed fuses, react almost instantaneously, protecting sensitive circuitry and transistors. Fast Acting Fuses, or F-Type, are more general-purpose, suitable for cabling and sturdier components. Slow Acting fuses, including Dual Element types, have a delay mechanism allowing them to withstand short, lower power surges without blowing, ideal for circuits with momentary current spikes.

Advantages and Disadvantages of Fuse Speeds

Ultra-rapid fuses offer the highest level of protection for sensitive electronics but can be more expensive. Fast Acting Fuses balance responsiveness with durability, making them versatile for various applications. Slow Acting fuses are ideal for circuits with fluctuating currents, but their delayed response may not be suitable for highly sensitive components.

Characteristics of Fuse Speeds

- Ultra-Rapid: Instantaneous response, ideal for sensitive electronics.

- Fast Acting: General-purpose, good balance of response time and durability.

- Slow Acting: Delay mechanism, tolerates short surges.

Use Cases of Different Fuse Speeds

Ultra-rapid fuses are used in delicate electronic equipment. Fast Acting Fuses are common in household and commercial electrical systems. Slow Acting fuses are preferred in systems with motors or other components that cause brief current spikes.

Types of Fuses: AC and DC Fuses

Working Principles of AC and DC Fuses

AC (Alternating Current) fuses are designed for circuits where the current direction alternates, offering resistance to electric arcs when they blow. DC (Direct Current) fuses, on the other hand, are used in circuits where the current flows in one direction, with voltage ratings indicating their maximum capacity.

Advantages and Disadvantages of AC and DC Fuses

AC fuses can handle higher voltages, making them suitable for standard power supplies. DC fuses, while crucial for DC circuits, have maximum voltage limitations that should not be exceeded to ensure safety.

Characteristics of AC and DC Fuses

- AC Fuses: Higher arc resistance, compatible with higher voltages.

- DC Fuses: Maximum voltage ratings, used in one-directional current flow.

Use Cases of AC and DC Fuses

AC fuses are common in household and industrial electrical systems, where alternating current is the standard. DC fuses are essential in applications like solar power systems, electric vehicles, and other electronics that utilize direct current.

Types of Fuses: Cylindrical and HRC Fuse Types

Working Principles of Cylindrical and HRC Fuses

Cylindrical fuses are a basic but widely used design, featuring a simple cylindrical shape. High rupturing capacity (HRC) fuses, on the other hand, include a transparent capsule made from rugged materials like steatite or epoxy resins around the central resistor, enhancing their capacity to handle high currents without rupturing.

Advantages and Disadvantages of Cylindrical and HRC Fuses

Cylindrical fuses are known for their simplicity and broad applicability. HRC fuses offer a higher breaking capacity, suitable for more demanding applications, but can be more expensive and larger in size.

Characteristics of Cylindrical and HRC Fuses

- Cylindrical Fuses: Basic design, versatile for various applications.

- HRC Fuses: High rupturing capacity, robust construction for higher current handling.

Use Cases of Cylindrical and HRC Fuses

Cylindrical fuses find use in a range of applications from consumer electronics to industrial equipment. HRC fuses are particularly suited for environments where high current or voltage conditions are prevalent, such as in industrial machinery or power distribution systems.

Types of Fuses: Car Fuses (Blade, Bolt-Down, and Cartridge Fuses)

Working Principles of Car Fuses

Car fuses, including blade, bolt-down, and cartridge types, serve as protective devices in automotive electrical systems. Blade fuses feature blades for easy insertion, bolt-down fuses are used for high current circuits, and cartridge fuses consist of a conductive material housing with a resistor wire.

Advantages and Disadvantages of Different Car Fuses

Blade fuses are compact and easy to replace, bolt-down fuses offer robust protection for high currents, and cartridge fuses are versatile and widely applicable. However, blade fuses can be challenging to handle due to their small size, and cartridge fuses might require additional tools for inspection.

Characteristics of Car Fuses

- Blade Fuses: Compact, color-coded, easy to install and replace.

- Bolt-Down Fuses: Robust design for high current circuits.

- Cartridge Fuses: General-purpose, compatible with a variety of devices.

Use Cases of Various Car Fuses

Blade fuses are commonly used in most modern vehicles for standard circuit protection. Bolt-down fuses find their use in more demanding automotive applications requiring high current handling. Cartridge fuses are used in older vehicles and a variety of automotive components.

Types of Fuses: Bolted Tag, Bottle, and Cartridge Fuses

Working Principles of Bolted Tag, Bottle, and Cartridge Fuses

Bolted tag fuses feature metal tags for bolting into fuse holders, mainly used in industrial settings. Bottle fuses are bottle-shaped with distinct ends, ensuring precise fitting and an indicator that shows when they blow. Cartridge fuses, familiar and general-purpose, have a cylindrical design with a conductive material housing and a resistor wire inside.

Advantages and Disadvantages of These Fuses

Bolted tag fuses are secure and reliable for industrial applications but may require tools for installation. Bottle fuses provide clear indication of fuse status but are specific to certain slots. Cartridge fuses are versatile and easy to replace but may not be suitable for high-current applications.

Characteristics of Bolted Tag, Bottle, and Cartridge Fuses

- Bolted Tag Fuses: Cylindrical shape, metal tags for secure installation.

- Bottle Fuses: Unique shape with an indicator, precise alignment with circuit adaptors.

- Cartridge Fuses: Common cylindrical design, made from various conductive materials.

Use Cases of Bolted Tag, Bottle, and Cartridge Fuses

Bolted tag fuses are used in a range of industrial and electrical equipment for low voltage circuits. Bottle fuses are often found in applications requiring precise fuse fitting and clear indication of status. Cartridge fuses are widespread in both household and commercial settings, suitable for a variety of devices and electrical systems.

Types of Fuses: Centred Tag, Offset Tag, and Slotted Tag Fuses

Working Principles of Tag Fuses

Tag fuses, including centred, offset, and slotted types, feature metal tags for connection. Centred tag fuses have a tag protruding from the center, offset tag fuses have asymmetrically positioned tags, and slotted tag fuses include a slot in the tag for secure connection.

Advantages and Disadvantages of Different Tag Fuses

Centred tag fuses provide a balanced design for consistent performance. Offset tag fuses offer versatility for different fuse holders, while slotted tag fuses ensure a secure connection. However, their specific designs might limit their use to particular applications or holders.

Characteristics of Tag Fuses

- Centred Tag Fuses: Balanced tag positioning for stability.

- Offset Tag Fuses: Asymmetrical tags for flexible installation.

- Slotted Tag Fuses: Slot design for secure mounting.

Use Cases of Tag Fuses

Tag fuses are commonly used in industrial and commercial electrical systems where secure and reliable connections are essential. Their specific designs cater to a variety of electrical equipment, ensuring safety and efficiency in high-demand settings.

Types of Fuses: Thermal and SMD Fuses

Working Principles of Thermal and SMD Fuses

Thermal fuses operate based on temperature, blowing when the surrounding temperature exceeds a certain threshold. SMD (Surface Mount Device) fuses, used on printed circuit boards, blow when overcurrent or short circuits occur, with resettable and non-resettable options available.

Advantages and Disadvantages of Thermal and SMD Fuses

Thermal fuses are ideal for heat-generating devices, offering targeted protection, but they must be replaced after blowing. SMD fuses are compact and versatile, with resettable variants being more cost-effective over time, but may have limitations in current handling compared to larger fuses.

Characteristics of Thermal and SMD Fuses

- Thermal Fuses: Temperature-sensitive, single-use.

- SMD Fuses: Compact, available in resettable and non-resettable forms.

Use Cases of Thermal and SMD Fuses

Thermal fuses are commonly found in household appliances like coffee machines, dryers, and hair dryers. SMD fuses are used in various electronic devices, offering space-saving circuit protection on printed circuit boards.

Types of Fuses: Striker, Type C, D, and F Fuses

Working Principles of Specialized Fuses

Striker fuses are equipped with a spring-loaded device that indicates a blown fuse and can trip adjacent switches. Type C, D, and F fuses are miniature circuit breakers (MCB) tripping at different overload levels. Type C trips at 5-10 times the rated current, Type D at 10-20 times, and Type F, also known as fast-blow fuses, respond quickly to excess current.

Advantages and Disadvantages of Specialized Fuses

Striker fuses offer clear indication and additional safety features. Type C, D, and F MCBs provide precise protection levels for various applications but may require careful selection based on specific circuit requirements.

Characteristics of Specialized Fuses

- Striker Fuses: Spring-loaded indicator for blown fuses.

- Type C MCBs: Trips at moderate overload levels.

- Type D MCBs: Suitable for higher overload protection.

- Type F Fuses: Fast response to current excess.

Use Cases of Specialized Fuses

Striker fuses are often used in industrial settings for safety and quick response. Type C MCBs are suited for residential and commercial circuits with moderate power demands. Type D MCBs are ideal for circuits with higher power requirements, while Type F fuses are used in applications needing rapid response to prevent damage, such as in electronic circuits.

Table of Comparison for All Types of Fuses

This comparative table offers a quick overview of the different types of fuses, highlighting their key features and suitability for various applications. This information is crucial for selecting the right type of fuse for specific electrical needs.

| Feature/Type | Ultra-Rapid, Fast, and Slow Acting | AC and DC Fuses | Cylindrical and HRC | Car Fuses | Bolted Tag, Bottle, Cartridge | Tag Fuses | Thermal and SMD | Striker, Type C, D, F |

| Speed/Response | Varied speeds for different needs | AC for higher voltages, DC for direct current | Basic design, HRC for higher currents | Variety for automotive needs | Secure, reliable in various settings | Secure connection, varied tag designs | Temperature or current triggered | Striker for indication, Types C, D, F for different overload levels |

| Use Cases | Sensitive electronics to general circuits | Household to solar power systems | Consumer electronics to industrial | Automotive and related applications | Industrial and electrical equipment | Industrial and commercial systems | Household appliances, electronic devices | Industrial, residential, and commercial circuits |

| Advantages | Matched to circuit sensitivity | Tailored to current type | Versatile, HRC for robust needs | Easy to replace, range of sizes | Durable, specific to circuit designs | Varied designs for specific installations | Targeted protection, compact design | Clear indication, precise protection levels |

| Disadvantages | Specific to application | Limited by voltage type | Basic, may not suit high-power needs | Small size may be challenging | May require tools for installation | Limited to specific holders | Must be replaced after blowing | Requires careful selection based on circuit |

This table provides an at-a-glance comparison, assisting in understanding the diverse types of fuses available and their appropriate applications for ensuring electrical safety and efficiency.

Conclusion

In the realm of electrical safety, the significance of choosing the correct type of fuse cannot be overstated. From the rapid response of ultra-rapid fuses to the targeted protection of thermal and SMD fuses, each type serves a specific purpose in safeguarding electrical circuits. This guide aimed to provide a comprehensive overview of the various types of fuses, their working principles, and appropriate applications.

Whether for household appliances, automotive systems, or industrial machinery, understanding the nuances of different fuses ensures not only the protection of electrical systems but also enhances safety and efficiency. The right fuse choice is a critical step in any electrical setup, embodying the principle that the best defense is a good offense. As we conclude, remember that in the intricate world of electrical systems, the small, often overlooked fuse plays a pivotal role in maintaining safety and functionality.

FAQs

- What is the main difference between AC and DC fuses?

AC fuses are designed for alternating current and can handle higher voltages, whereas DC fuses are for direct current circuits and have maximum voltage limitations. - When should I use a slow acting fuse instead of a fast acting one?

Use a slow acting fuse in circuits with momentary current spikes, like those with motors, as they can tolerate short surges without blowing. - Are thermal fuses reusable after they blow?

No, thermal fuses are designed for single use and must be replaced after they blow. - What type of fuse is best for sensitive electronic equipment?

Ultra-rapid fuses are best for sensitive electronics as they react almost instantaneously to overcurrent, offering the highest level of protection. - Can I replace a cartridge fuse with a blade fuse in my car?It depends on the fuse holder in your car. Blade fuses are common in modern vehicles, but it’s important to use the type of fuse that fits the holder and meets the circuit’s requirements.

- What is the purpose of a striker fuse?

Striker fuses have a spring-loaded striking device that indicates when the fuse has blown and can also trip adjacent switches for added safety.