Capacitors are fundamental Electrical Components in the world of electronics, serving a wide array of functions from energy storage to noise filtering. Their versatility and efficiency make them indispensable in both everyday and specialized electronic devices. Understanding the different types of capacitors is crucial for anyone involved in electronics, whether you’re a hobbyist, student, or seasoned engineer.

In this comprehensive guide, we will explore the various types of capacitors, focusing on their unique properties and applications, and how they fit into the broader landscape of electrical components. Additionally, we will touch on other key components like the types of rectifiers, types of bridge rectifiers, and types of resistors that play critical roles in electronic circuits.

From commonly used ceramic capacitors to high-capacity supercapacitors, each type offers distinct advantages and disadvantages to meet different requirements and challenges in electronic circuits. Our journey will not only highlight these differences but also explain their working principles and characteristics.

Stay tuned as we explore the fascinating and diverse types of capacitors, alongside other essential electrical components, a crucial topic for anyone passionate about electronics and their vast possibilities.

Achieve a new standard of efficiency with LinkSemi’s Excess Electronic Components Platform, tailored to streamline inventory sales and reduce excess costs. We deliver outstanding Electronic Component Cost Savings using AI-powered insights and automated workflows. Furthermore, our cutting-edge Electronic Component Shortage Module helps prevent supply chain disruptions, ensuring seamless production and continuous operational efficiency.

Types of Capacitors 1: Ceramic Capacitors

Working Principles of Ceramic Capacitors

Ceramic capacitors are among the most widely used types of capacitors in the electronics industry. Their basic working principle involves two metal plates separated by a ceramic dielectric. When a voltage is applied, an electric field is created in the dielectric, storing energy electrostatically. The specific properties of the ceramic material, such as permittivity, greatly influence the capacitor’s overall performance, including its capacitance value.

Advantages and Disadvantages of Ceramic Capacitors

Advantages:

- High Stability and Reliability: Ceramic capacitors are known for their exceptional stability and reliability over a wide range of temperatures and frequencies.

- Compact Size: These capacitors come in a variety of sizes, often very small, making them ideal for densely packed circuits.

- Non-Polarized Nature: This makes them suitable for both AC and DC applications.

Disadvantages:

- Limited Capacitance Range: They generally offer lower capacitance values compared to other types, limiting their use in high-capacity applications.

- Voltage Sensitivity: Some ceramic capacitors can experience changes in capacitance with applied voltage.

Characteristics of Ceramic Capacitors

Ceramic capacitors are characterized by their low inductance and high-frequency capabilities, making them well-suited for high-speed applications. They are typically available in a range of capacitance values, from a few picofarads to several microfarads. Their temperature coefficient can vary, which is often designated by a code on the capacitor itself, indicating their suitability for different operating conditions.

Use Cases for Ceramic Capacitors

Due to their stability and high-frequency performance, ceramic capacitors are commonly used in:

- RF and Microwave Circuits: For tasks like signal coupling and noise filtering.

- Power Supply Circuits: Serving as bypass or decoupling capacitors to filter out noise from power lines.

- Consumer Electronics: In devices like smartphones, televisions, and other compact electronics due to their small size.

Types of Capacitors 2: Electrolytic Capacitors

Working Principles of Electrolytic Capacitors

Electrolytic capacitors are distinctive for their use of an electrolyte to achieve higher capacitance values. These capacitors typically consist of two metal plates, where one plate is coated with an oxide layer that acts as the dielectric. The electrolyte, which can be either liquid or gel, makes up the second plate. This unique construction allows for a larger plate area and thinner dielectric layer, resulting in significantly higher capacitance values compared to other types of capacitors.

Advantages and Disadvantages of Electrolytic Capacitors

Advantages:

- High Capacitance: Electrolytic capacitors offer much higher capacitance values, making them suitable for high-capacity storage needs.

- Voltage Ratings: They come in a wide range of voltage ratings, accommodating various circuit requirements.

Disadvantages:

- Polarization: Electrolytic capacitors are polarized components, which means they must be connected correctly in circuits to prevent damage.

- Limited Lifespan: The electrolyte can dry out over time, leading to a reduced lifespan, especially at higher temperatures.

Characteristics of Electrolytic Capacitors

Electrolytic capacitors are known for their large capacitance-to-volume ratio. However, they have larger tolerances, meaning the actual capacitance may vary more from the stated value compared to other types. They also exhibit higher equivalent series resistance (ESR) and inductance (ESL), which can affect their performance at high frequencies.

Use Cases for Electrolytic Capacitors

Electrolytic capacitors are often used in:

- Power Supply Circuits: As smoothing capacitors to reduce voltage ripple after rectification.

- Audio Applications: In loudspeaker crossover networks and power amplifiers, where large capacitance values are required.

- Energy Storage: In applications requiring temporary storage of large amounts of energy, such as in flashlights or power backup systems.

Types of Capacitors 3: Super Capacitors

Working Principles of Super Capacitors

Super capacitors, also known as ultracapacitors, operate on a different principle compared to traditional capacitors. They store energy electrostatically by polarizing an electrolytic solution. Unlike conventional capacitors that use a solid dielectric, super capacitors have electrodes coated with a porous material, typically activated carbon, and an electrolyte. The large surface area of the electrodes allows for a much higher capacitance, as energy storage is directly proportional to the contact area and inversely proportional to the distance between the electrodes.

Advantages and Disadvantages of Super Capacitors

Advantages:

- Exceptionally High Capacitance: Super capacitors can store a significantly larger amount of energy than standard capacitors.

- Fast Charging and Discharging: They can be charged and discharged much quicker than batteries.

- Longer Life Cycle: Super capacitors can endure millions of charge/discharge cycles without significant degradation.

Disadvantages:

- Lower Energy Density: While they have high power density, their energy density is lower than batteries, meaning they hold less total energy.

- Voltage Limitations: They typically have lower operating voltages, which necessitates the use of multiple capacitors in series for higher voltage applications.

- Higher Cost: Super capacitors are generally more expensive than other types of capacitors.

Characteristics of Super Capacitors

Super capacitors are characterized by their ability to provide a quick burst of energy. They have a wide range of capacitance values, often rated in farads. These capacitors also tend to have a linear discharge curve, providing a consistent voltage output until depleted, which is beneficial in stabilizing power supply in various applications.

Use Cases for Super Capacitors

Super capacitors are increasingly used in applications where rapid energy storage and release are essential, such as:

- Energy Harvesting: In systems where energy is collected from renewable sources like solar or kinetic energy.

- Power Backup: Providing short-term uninterrupted power supply during power outages.

- Automotive Applications: In regenerative braking systems of electric vehicles to capture and reuse energy.

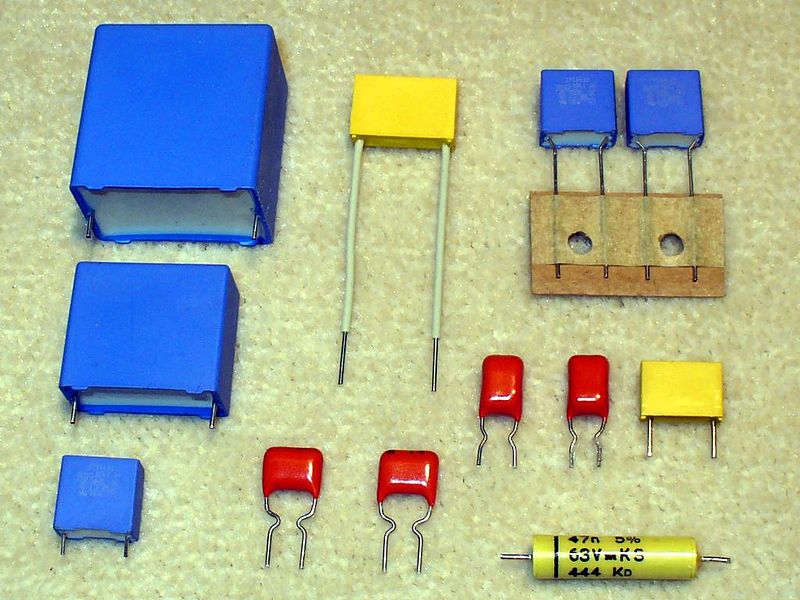

Types of Capacitors 4: Film Capacitors

Working Principles of Film Capacitors

Film capacitors use a thin plastic film as the dielectric, which is either metallized or covered with metal foil to form the electrodes. This film is wound or stacked to create a capacitor. The type of plastic used (such as polyester, polypropylene, or polystyrene) significantly influences the capacitor’s properties. The dielectric film determines the capacitor’s electrical characteristics, including its stability, capacitance, and voltage rating.

Advantages and Disadvantages of Film Capacitors

Advantages:

- High Stability and Low Distortion: Film capacitors offer excellent stability and low distortion, making them ideal for sensitive applications.

- Wide Range of Applications: Their versatility allows use in both high-frequency and high-power applications.

- Non-Polarized Design: Suitable for AC and DC circuits.

Disadvantages:

- Size: They are generally larger than other types of capacitors like ceramic or electrolytic capacitors, especially at higher capacitance values.

- Cost: Film capacitors tend to be more expensive than other types, like ceramic capacitors.

Characteristics of Film Capacitors

Film capacitors are known for their high precision and reliability. They exhibit very low dielectric absorption and have a wide range of temperature tolerance. These capacitors are also known for their excellent frequency characteristics, making them suitable for applications that require high accuracy.

Use Cases for Film Capacitors

Film capacitors are used in a variety of applications, including:

- Power Electronics: For filtering, snubbers, and energy storage in applications like motor drives and inverters.

- Audio Electronics: In audio circuits for signal coupling and crossover networks due to their low distortion.

- Automotive Electronics: In applications requiring durability and reliability under varying environmental conditions.

Table of Comparison for the 4 Main Types of Capacitors

The following table provides a concise comparison of Ceramic, Electrolytic, and Super Capacitors, highlighting key differences in their characteristics and typical applications:

| Feature/Type | Ceramic Capacitors | Electrolytic Capacitors | Super Capacitors |

| Basic Construction | Metal plates with ceramic dielectric | Metal plates with electrolyte as one plate | Electrodes with activated carbon & electrolyte |

| Capacitance Range | Low (pF to µF) | Medium to High (µF to mF) | Very High (Farads) |

| Size/Form Factor | Small and compact | Larger, cylindrical | Varies, often larger |

| Voltage Rating | Low to Medium | Wide range, higher than ceramic | Generally lower |

| Polarization | Non-polarized | Polarized | Non-polarized |

| Stability & Reliability | High | Medium (limited by electrolyte lifespan) | High |

| Frequency Response | Excellent at high frequencies | Limited at high frequencies | Good for quick charge/discharge cycles |

| Primary Use Cases | Signal coupling, noise filtering, RF applications | Power supplies, audio systems, energy smoothing | Energy harvesting, power backup, automotive applications |

| Cost | Generally low | Low to Medium | Higher |

| Lifespan | Long | Shorter, depends on usage and temperature | Very long |

This table serves as a quick reference to understand the fundamental differences between these types of capacitors, aiding in making an informed decision based on the requirements of your specific electronic projects or applications.

Takeaways

In this guide, we have navigated the intricate world of capacitors, shedding light on the distinct types, each with its unique set of properties and applications. From the compact and versatile Ceramic Capacitors to the high-capacity and quick-charging Super Capacitors, understanding these variations is crucial for anyone engaged in electronics design and implementation.

Choosing the right capacitor can be the key to ensuring optimal performance and longevity of electronic circuits. Whether you’re working on a simple DIY project or a complex industrial application, the knowledge of these capacitor types empowers you to make informed decisions tailored to your specific needs.

As technology continues to evolve, so too will the capabilities and applications of capacitors. Staying informed about these advancements is essential for anyone in the field of electronics. We hope this guide serves as a valuable resource in your electronic endeavors, helping you harness the full potential of these remarkable components.

FAQs

- What are the key factors to consider when choosing a type of capacitor for a project?

When selecting a capacitor, consider factors like capacitance value, voltage rating, size, temperature stability, frequency response, and lifespan. The choice depends on the specific requirements of your application, such as energy storage capacity, space constraints, and environmental conditions. - Can I replace one type of capacitor with another in a circuit?

It’s not always advisable to substitute capacitors of one type for another due to differences in electrical characteristics. Such replacements can lead to changes in circuit performance or even damage. Always consider the specific requirements of the circuit and the characteristics of the capacitors. - Why are super capacitors not commonly used in place of traditional capacitors despite their high capacitance?

While super capacitors offer high capacitance, their lower energy density and higher costs limit their use to specific applications where these characteristics are advantageous. They are typically used for energy storage and rapid charge/discharge applications rather than in traditional capacitor roles. - How does temperature affect the performance of different types of capacitors?

Temperature can significantly impact capacitor performance. Ceramic capacitors generally offer stable performance across a wide temperature range, while electrolytic capacitors can degrade more quickly at higher temperatures. Super capacitors also tend to have a stable performance over a wide temperature range. - Are there any environmental concerns associated with the use of certain types of capacitors?

Some capacitors, especially certain types of electrolytic capacitors, can contain environmentally harmful materials or chemicals. Disposal and recycling of these capacitors should be handled properly to avoid environmental damage. - What are the 4 main types of capacitors?

The four main types of capacitors discussed in this guide are Ceramic Capacitors, Electrolytic Capacitors, and Super Capacitors.