Electric motors are fundamental to modern technology, powering everything from household appliances to advanced industrial machinery. Essentially, electric motors transform electrical energy into mechanical energy, supplying the motion and force required in a multitude of applications. The range of designs and functions in electric motors is extensive, meeting specific needs across various sectors.

In this guide, we explore the different types of electric motors, examining their operating principles, advantages, limitations, and applications. Whether you’re an experienced engineer, a student, or simply interested in the mechanisms behind these essential devices, this journey into the world of electric motors provides insights to broaden your understanding. Stay tuned as we delve into the 3 main types of electric motors and other crucial information, including related components such as types of LED drivers, essential to Power and Energy management.

What are Electric Motors?

Electric motors are fascinating and integral components in a wide array of devices and systems around us. At their core, electric motors are machines that convert electrical energy into mechanical energy. This conversion is achieved through the interaction of magnetic fields and winding currents, resulting in force and motion. There are more than a few types of electric motors, each with unique properties and suited for specific applications.

The basic components of an electric motor typically include a rotor, which is the moving part, and a stator, the stationary part. These components work together within the motor’s electromagnetic environment to create rotation. Electric motors are essential in numerous applications, ranging from small devices like electric toothbrushes to large industrial machinery. They are the driving force behind many modern conveniences and technologies, making them a pivotal element in our day-to-day life and the broader industrial landscape.

Understanding the different types of electric motors, such as AC (Alternating Current) motors, DC (Direct Current) motors, and brushless DC motors, is crucial in selecting the right motor for a specific task. Each type has distinct characteristics in terms of efficiency, speed control, size, and power source compatibility. This guide will provide an in-depth look at these variations, helping you grasp the versatility and functionality of electric motors.

Types of Electric Motors 1: AC Motors

Working Principles of AC Motors

Alternating Current (AC) motors are among the most widely used electric motors, renowned for their simplicity and effectiveness. The fundamental principle behind AC motors is the use of alternating current to generate rotating magnetic fields. This rotation is achieved through the interaction between the motor’s stator, which generates a magnetic field when AC electricity is applied, and the rotor, which turns in response to this field. The synchronous speed of the motor, which is the speed at which the magnetic field rotates, depends on the frequency of the AC power supply and the number of coils in the motor.

Advantages and Disadvantages of AC Motors

AC motors boast several advantages. They are generally more durable and require less maintenance than DC motors, mainly because they lack brushes that wear out. Additionally, they are more cost-effective and can handle larger power loads, making them suitable for heavy-duty industrial applications. However, AC motors have some drawbacks. They typically offer less precise speed control compared to DC motors and might not be the best choice for applications requiring high precision or variable speed control.

Characteristics of AC Motors

AC motors are characterized by their robust design and efficiency. They come in various types, such as induction motors and synchronous motors, each with unique features. Induction motors, for instance, are known for their ruggedness and simplicity, while synchronous motors are valued for their ability to maintain a constant speed regardless of load variations.

Use Cases of AC Motors

These types of electric motors find widespread use in a plethora of applications. They are commonly found in home appliances like refrigerators and washing machines, HVAC systems, and industrial machinery. Their ability to handle high power makes them suitable for applications like pumps, fans, and conveyors in industrial settings.

Types of Electric Motors 2: DC Motors

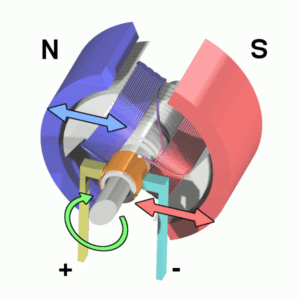

Working Principles of DC Motors

Direct Current (DC) motors operate on a different principle compared to their AC counterparts. In a DC motor, electricity is supplied to the armature (rotating part) through a commutator and brushes, creating a magnetic field that interacts with the field created by the stator (stationary part). This interaction causes the armature to rotate. The speed of a DC motor can be easily controlled by varying the voltage applied to the armature, making it highly suitable for applications where speed control is crucial.

Advantages and Disadvantages of DC Motors

One of the primary advantages of DC motors is their precise speed control. They offer a wide range of speeds, making them ideal for applications that require varying motor speeds. Additionally, DC motors provide high starting torque, which is beneficial for applications needing a strong initial push. However, the presence of brushes in DC motors leads to more wear and tear, necessitating more maintenance. They are also generally more expensive than AC motors and less suitable for high-power applications due to their size and heat generation.

Characteristics of DC Motors

DC motors are known for their high torque and precise speed control. They come in various types, including brushed and brushless designs. Brushed DC motors are more traditional and simpler in design, but brushless DC motors offer enhanced efficiency, longer life, and less maintenance due to the absence of brushes.

Use Cases of DC Motors

These types of electric motors are widely used in applications where motor speed needs to be precisely controlled. They are commonly found in electric vehicles, robotics, and small home appliances. Their high torque also makes them suitable for applications like electric winches and cranes, where a strong initial force is required.

Types of Electric Motors 3: Brushless DC Motors

Working Principles of Brushless DC Motors

Brushless DC (BLDC) motors represent a significant advancement in the field of electric motors. Unlike traditional DC motors, BLDC motors do not have brushes. Instead, they use an electronic controller to switch the phase to the windings, thereby generating a rotating magnetic field that drives the motor. This design significantly reduces the need for maintenance and increases the motor’s lifespan. The electronic control system also allows for more precise speed and torque control, making BLDC motors highly efficient and reliable.

Advantages and Disadvantages of Brushless DC Motors

The primary advantage of these types of electric motors is their high efficiency and reliability due to the absence of brushes, which are prone to wear and tear. This feature extends the lifespan of the motor and reduces maintenance requirements. Additionally, BLDC motors are known for their high power-to-size ratio, making them ideal for space-constrained applications. However, they are typically more expensive than brushed DC motors and require a more complex control system, which can increase the overall cost and complexity of the applications in which they are used.

Characteristics of Brushless DC Motors

BLDC motors are characterized by their excellent thermal and energy efficiency, high torque-to-weight ratio, and quiet operation. They also offer better speed-versus-torque characteristics and more dynamic response than brushed DC motors. The absence of brushes allows for more efficient cooling and reduces the generation of electromagnetic noise.

Use Cases of Brushless DC Motors

These types of electric motors are ideal for applications where efficiency and reliability are paramount. They are extensively used in electric vehicles, drones, and high-precision industrial applications. Their compact size and high efficiency make them suitable for use in consumer electronics, such as computer hard drives and DVD players, as well as in medical devices where precise and reliable motor control is critical.

Table of Comparison for 3 Types of Electric Motors

The following table provides a comparative overview of the three primary types of electric motors discussed: AC Motors, DC Motors, and Brushless DC Motors. This comparison will help in understanding the key differences and similarities among these motor types, aiding in selecting the appropriate motor for specific applications.

| Feature/Type | AC Motors | DC Motors | Brushless DC Motors |

| Principle of Operation | Uses alternating current to create a rotating magnetic field. | Uses direct current, with brushes for commutation. | Uses direct current with an electronic controller for commutation. |

| Speed Control | Less precise, typically requires additional equipment for speed control. | Precise control, easily adjustable speed. | Highly precise, enabled through electronic control. |

| Maintenance | Low maintenance, more durable due to lack of brushes. | Higher maintenance due to brush wear. | Minimal maintenance, no brushes to wear out. |

| Efficiency | Generally efficient, especially in larger sizes. | Less efficient due to brush friction. | High efficiency, no energy loss due to brush friction. |

| Cost | Generally less expensive. | Moderate cost, depends on size and type. | Usually more expensive due to complex control systems. |

| Torque | Consistent torque, varies with type (induction, synchronous). | High starting torque. | High torque, efficient torque management. |

| Typical Applications | Household appliances, industrial machinery. | Electric vehicles, robotics, small appliances. | Electric vehicles, drones, high-precision industrial applications. |

This table underscores the distinct characteristics of each motor type. While AC motors are commonly used for general industrial applications due to their durability and cost-effectiveness, DC motors are favored in applications requiring precise speed control. As the third in our list of 3 types of electric motors, Brushless DC motors are increasingly popular in advanced and high-precision applications. That is mainly due to their high efficiency and low maintenance requirements.

Conclusion

In our exploration of the different types of electric motors, we have seen how each type offers unique advantages and is suited for specific applications. From the robust and versatile AC motors to the precise and efficient DC and Brushless DC motors, the choice depends largely on the requirements of the application in question. Understanding these variations is crucial for engineers, designers, and even enthusiasts who wish to make informed decisions when it comes to selecting the right motor.

As technology continues to advance, we can expect further innovations in electric motor design and functionality. These advancements will likely lead to even more efficient, powerful, and versatile motors, catering to an ever-expanding array of applications. The world of electric motors is dynamic and evolving, and it remains a key component in the advancement of various industries and technologies. If you liked this guide on 3 types of electric motors, make sure to check out our guide on the 4 Main Types of Flip Flops with Application.

FAQs

- What is the main difference between AC and DC motors?

The main difference lies in their power source and construction. AC motors are powered by alternating current and typically have a simpler design with fewer moving parts, whereas DC motors use direct current and usually have brushes for commutation. - Why are Brushless DC Motors more expensive than traditional DC Motors?

Brushless DC motors are more expensive due to their complex electronic control systems, which are required for commutation and precise control. This complexity, however, offers benefits like higher efficiency and lower maintenance. - Can the speed of an AC motor be controlled?

Yes, the speed of an AC motor can be controlled, but it usually requires additional equipment like variable frequency drives (VFDs) to adjust the power supply frequency, thereby controlling the motor speed. - Where are Brushless DC Motors most commonly used?

Brushless DC motors are commonly used in applications where efficiency and reliability are critical, such as in electric vehicles, drones, and high-precision industrial and medical equipment. - What makes DC motors suitable for electric vehicles?

DC motors, particularly brushless DC motors, are suitable for electric vehicles due to their high torque, efficient power consumption, and ability to provide precise speed control, which is essential for the performance and efficiency of electric vehicles.